Article classificationArticle

HEPCOMOTION AND KUKA PROVIDE AUTONOMOUS MACHINING PRT2 Ring guide

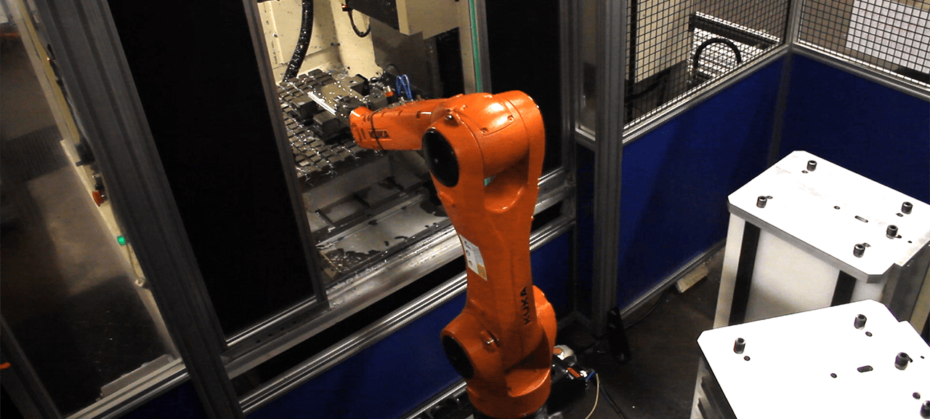

With a need to meet the growing demand for its products and to shorten lead times, linear motion expert HepcoMotion recently invested in a KUKA robot to automate the loading and unloading of one of its CNC milling machines. 2016 was extremely successful for Hepco in terms of sales and the move to automate was a natural step for Hepco’s manufacturing capabilities. Still in its first year at Hepco, the KUKA KR 10 R1100 sixx (KR AGILUS) is enabling Hepco to machine overnight, and subsequently increase production and offer shorter lead times on its standard products.

Autonomous loading and unloading improves productivity

Based at Hepco’s headquarters in Tiverton, Devon, the RoboDrill T21i CNC milling machine using the robot automation is producing carriage plates for Hepco’s portfolio of products. Hepco offers over forty-two major product lines with thousands of individual components in various sizes. Each linear and rotary product requires a carriage plate; the robot therefore needs to be able to work with differing sizes and materials.

In this application, the machinist loads the sawn blanks into a carousel; the robot then picks a sawn blank and loads it into the CNC machine. The machine carries out the drilling and milling work; the robot then returns the finished carriage plate back into the exact space in the carousel that it was taken from. The robot movement is controlled via Omron PLC control.

Thanks to its robust design, the KR AGILUS sixx achieves maximum repeatability and continuous precision. With its extreme speed, it reduces cycle times – and increases production quality, without ever getting out of step.

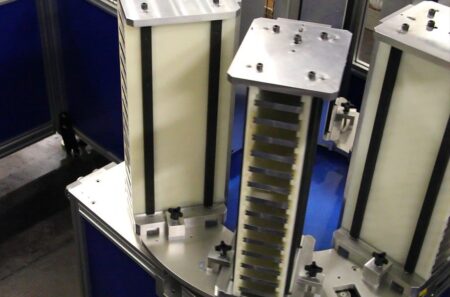

There is space for 84 plates to be loaded in the carousel – with 6 stacks on the carousel each containing 14 plates. The cycle time depends on the size of the carriage plates but can be between 9-14 minutes per plate, including the robot changeover time. Again, depending on the product, the complete batch cycle time is between 13-21 hours. Over a prolonged period of time, and working nights and weekends, this autonomous process offers increased efficiency. The robot has enabled Hepco to increase production to put more products in stock, ready to provide quick delivery times.

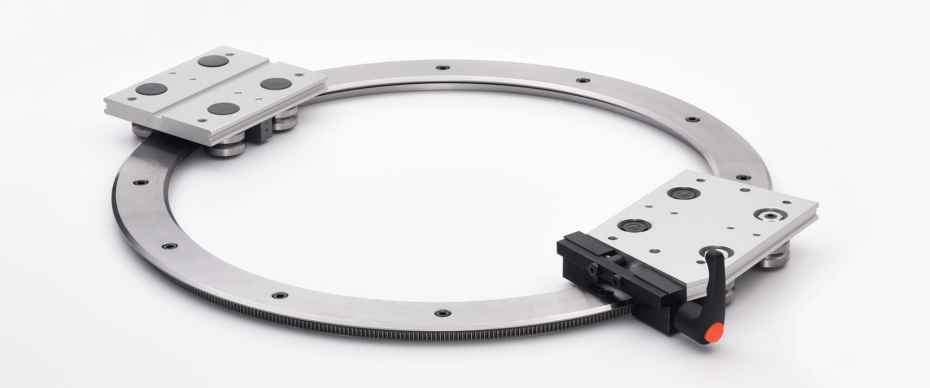

Hepco’s utilises its own PRT2 ring guide

The carousel holding the metal plates is made from Hepco’s PRT2 ring guide and this is indexed through the Omron HMI PLC Control to turn as necessary to rotate the un-machined plates for the robot to pick up. This ring system has an integrated rack and pinion drive and offers complete 360 degree, or segmental motion – allowing the table to be indexed to the correct station with repeated accuracy. With a load range of up to 9,300N, PRT2 can cater for a range of applications.

The carousel and robot are situated next to the CNC machine behind a safety cage made of Hepco’s MCS aluminium profiles to ensure the safety of the workers. In implementing a robot cell one of the major considerations is the safety of operators and people working in the area. Guard doors are interlocked with safety gate switches such that control power to all moving parts is isolated prior to opening the actual guard doors.

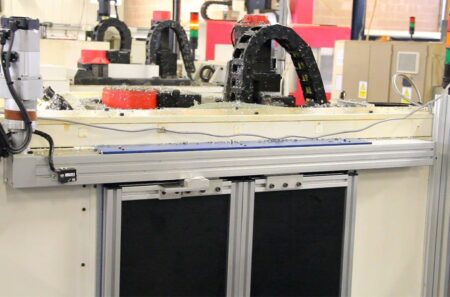

Hepco’s actuators provide the machine door automation

The sliding safety doors connecting the robot cell and the CNC machine are fitted with Hepco’s DAPDU2 dual action linear actuator; a double acting system that is ideal for driving automatic doors in a variety of manufacturing applications. The doors are constructed using MCS aluminium profiles, and the two carriages run symmetrically and open simultaneously, achieving speeds up to 6m/s. The double acting system allows two narrower doors to be used, therefore the physical space required is kept to a minimum. Access to the CNC machine is thereby available to use quicker.

The need to automate was driven by the requirement to fulfil orders more quickly and to keep pace with the growing demand for Hepco products. The ability to run overnight without a machinist present has certainly achieved this. As a world-leading manufacturer of linear motion systems, and with branches and distributors in 41 countries, Hepco continues to employ new technology to its experienced manufacturing capability.