Article classificationArticle

FOOD INDUSTRY CLEANING APPLICATION GV3

This customer was using an existing system of shaft and ball bushings that were failing due to the hostile conditions present from cleaning trays for bread, using an abrasive compound forced under pressure.

With abrasive in the atmosphere any linear solution would need to be able to withstand the conditions plus an offset load of 16kg, 125mm extended from the linear system. The previous ball bushing arrangement required a bellows cover and 4 ball bushings with two shafts in parallel that needed to be set parallel to ensure easy running. The stroke required was 700mm the drive was by pneumatic cylinder.

Solution

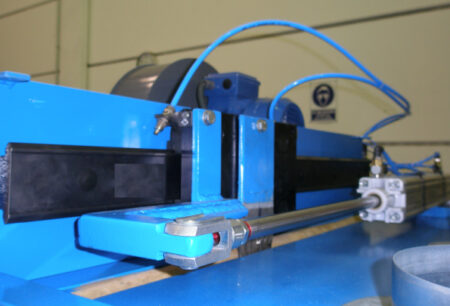

One double edge slide size NL76 from the GV3 range complete with assembled carriage to fit the cylinder and cleaning head to. Cap seals provide positive lubrication for the slide and prevent dirt ingress.

Scope of supply

NL76 P3 slide – 1079mm long complete with carriage AU7654 L300CSDR

Result

Replacing two shafts in parallel is a common occurrence for GV3 as customers can take advantage of a single slide that only needs to be bolted down. There is no requirement to ensure parallel running as the slide has in-built parallelism. With a wide range of slide widths on offer, the customer can select the right slide that will be able to withstand the load and achieve the duty cycle. Because V Guide technology is used, the customer is safe in the knowledge that the system will operate in the hostile conditions and provide a long and trouble free life. GV3 is proven in hostile conditions even without cap wipers as the self cleaning effect removes debris from the vee running surfaces.