Article classificationArticle

LOW MAINTENANCE GANTRY SYSTEM IMPROVES CONSISTENCY AND QUALITY OF A MULTI-STATION CHEMICAL FINISHING

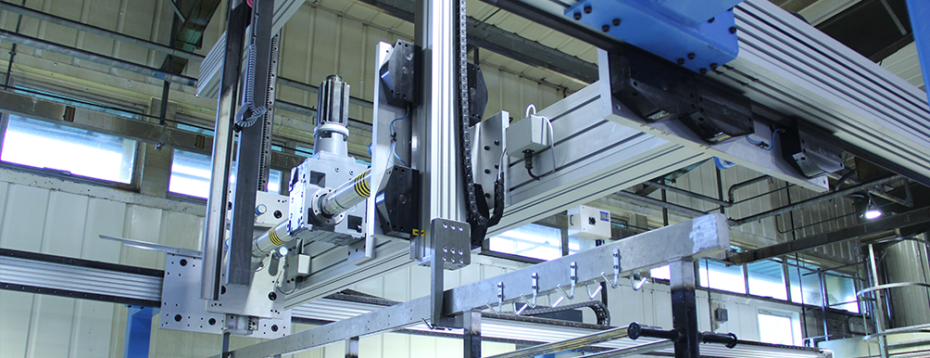

Linear motion expert HepcoMotion has recently upgraded its core blacking process system with the use of its own HDS2 rack driven gantry system to dip its slides, rings and track system into a multi-station chemical finishing dipping plant.

The blacking process changes the colour of metal items to black, which improves the visual appearance, providing uniformity and consistency. The blacking process is a key part of Hepco’s manufacturing process with all products apart from stainless steel or special orders being blackened.

The dipping plant spans across 16 metres with 7 separate dipping tanks (4 tanks with chemicals and 3 clean water rinse tanks). The slides are held in a dipping module which can accommodate up to 16 x 4.32 metre lengths of slide at one time. The dipping module is then picked up by the gantry, moved forwards and then lowered into each of the 7 tanks in turn. The gantry is constructed from HepcoMotion’s HDS2 heavy duty linear guides which has a wide range of V bearings and linear components to handle the heaviest loads. Hepco’s HDS2 gantry is ideally suited to this application as it is a high capacity system with low maintenance features.

X-axis

The X-axis comprises of 2 x HB25 aluminium beams at 16.16m long, each fitted with two single edge HD slides. V slides are used on one beam and flat tracks on the other beam, providing allowances for the variation in parallelism between the two beams. Parallelism of +/- 2.5mm ensures the set up time needed to accurately assemble the system is reduced. Moreover, the tolerance of misalignment ensures the system is able to cope with the offset loads. The slides are rack cut and fitted with MOD 3 rack option. 6 bearing carriages are used to accommodate the higher load.

Moving at a nominal speed of 0.5m/s, the X-axis has been optimised to move at a steady and smooth speed to ensure the slides remain securely on the dipping module. The slides cannot be fastened to the module as this would cause non-blacked areas on the slide. HDS2 can move up to 4 m/s but this speed is not required for this application.

Z-axis

With a payload of 700kg, HDS2 ESR slides (HSS25ESR) are used on the Z-axis, offering up to 4 times the load capacity of the standard HDS2 slide. ESR slides are precision machined from high quality steel and are surface hardened to provide excellent load capacity and wear resistance. Supplied with a MOD 5 rack, these slides have been designed to mount directly to Hepco’s range of HDS2 components, saving on valuable assembly time. The slides are mounted to a beam, housing the motors, gearboxes and drive shafts to provide the vertical and horizontal movement.

The Z-axis moves at 0.5 m/s with a stroke length of 1.5 metres to raise and lower the slides into the dipping tank. Two heads are utilised to provide stability manoeuvring the 4 metre lengths; a challenging shape and size. The time spent in the tank varies from 30 seconds to 240 seconds, depending on the individual tank. Between each chemical tank, the slides are submerged in a clear water rinse tank to rinse the slides off and to prevent cross contamination of the chemicals in the process.

Repeatable movement

As the dipping module is moved from one tank to another, a smooth and repeatable movement is paramount. The system aligns the dipping module to repeatable positions along the 16 metre gantry to +/- 0.25mm, ensuring the slides are accurately positioned above the corresponding tanks to be lowered into. The gantry is programmed to move from the start position, to each of the seven tanks at set intervals, and then accurately back to the start position. This is possible due to the drivers and gearboxes selected, as well as the rigidity and accuracy of Hepco’s HDS2.

Low maintenance

Being a high duty application covering long distances with heavy loads, the need to be low maintenance was a key driver. Any machine downtime with the blacking process has the potential to impact on orders and delivery times, so it was key for the system to deliver continuous operation, without the need to be stopped regularly for routine maintenance such as re-lubrication.

Low maintenance cap wipers are used, providing effective sealing and protection, whilst also wiping debris from the guide profile. The gantry also has an automatic lubrication system which delivers lubricant directly to the contact surfaces between the slide and the V bearings, ensuring that lubrication is constantly supplied to the slide. The system does not need to be stopped at regular intervals for re-lubrication, reducing downtime and increasing machine efficiency.

When maintenance is required, the process is simple and does not impinge too much on production time.

All bearings used in Hepco’s HDS2 gantry carriages are the removable type and can be dismounted from the carriage without the need to remove the carriage from the end of the axis. This means the whole process is very quick and can be achieved with minimal downtime. Under lubricated conditions, there is also no need to change the guide.

V Guide Technology

Hepco’s HDS2 gantry system is based on its precision V guide technology. Hepco’s V guide system has a unique wiping action that expels debris, making it perform particularly well in harsh, industrial environments, such as Hepco’s manufacturing headquarters. The outer diameter of the bearing travels at a faster speed than the inner diameter. The difference in speed causes particles nearer the centre to move outwards to the periphery, and to be expelled. Due to the geometry of the slide and bearing interface, debris is expelled to the outer diameter of the bearing in a spiral motion, away from the running surface.

Quality and consistency

The previous linear system used by HepcoMotion worked by sending the slides on conveyors, with the chemicals sprayed onto the slides as they passed through different spray booths. The biggest problem with this system was the quality and inconsistency, as the surfaces of the finished slides were not consistently covered in the black colour. Moreover, a minimum of three people were required to operate the old system, whereas the new automated system requires only one person, resulting in a significant reduction in labour. Processing 0.9 metres of narrow section slide every minute, the new gantry system has improved both the quality and consistency of the finished product as well as reducing the number of operators needed.