Article classificationArticle

XZ CUTTING SYSTEM FOR FOOD MANUFACTURE DLS

This German food machinery manufacturer supplying equipment to Saudi Arabia needed an XZ cutting system that would be robust enough to cut cake blocks into strips and be able to perform 24 hours a day.

The frozen cake blocks were required to be cut ultrasonically with cycles up to 30 per min with strokes of 1.5 x 0.5m. The key requirement would be reliability in service given that the machine would need to run 24 hrs / day 7 days per week.

Solution

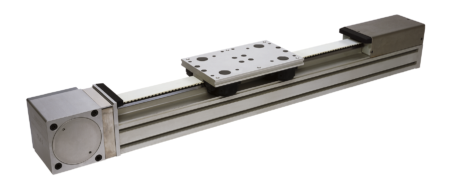

For the X axis, a corrosive resistant DLS5 with a stroke of 1.5 metres was used. Given the relative close proximity to the cake, food lube grease was used in the linear system bearings. To mount the Z axis and to provide sufficient rigidity a 300x 300mm square plate was fitted directly to the DLS5 carriage. Given the need to position the Z axis to an accurate vertical position a ball screw driven SDM unit was used with the ultrasonic knife fitted to the base. All driven units fitted with servo motors with location flanges tailored to suit the motor size. The whole arrangement was fitted to a steel frame.

Scope of Supply

1x CRDLS5 – L2030 F.O.R. with food lube grease, Connection plate 300 x 300 x 15mm. 1 x SDM 30-100 L775 2005 B2 ball screw driven unit. MCK motor connection kits for both axes.

Result

The strong cross section the DLS5 unit used in the X axis provides the necessary rigidity for the Z axis without additional support. Orientated so that the linear V groove bearings in the DLS5 carriage see the load radially also ensures that maximum load capacity is derived from the set up. The sealed ball screw driven SDM unit in the vertical axis maintains the cleanliness required for a food processing application and enables accurate positioning of the cutting knife. All units have been sized to provide minimal maintenance over the life of the machine.