Article classificationArticle

KOREAN PHARMACEUTICAL MANUFACTURERS RELY ON PROVEN HEPCO TRACK SYSTEMS IN THE BATTLE AGAINST CORONAV

Few of us could have anticipated the impact that Coronavirus would have on our lives when it was first reported at the beginning of this year. Shielding and isolation might have prevented the worst of this disease, creating a new culture of Zoom meetings, weekends spent tending to the garden and catching up with DIY, but many companies in the pharmaceutical and manufacturing sectors have not stopped.

Food producers face new challenges to ensure entire nations are fed, while pharmaceutical companies race to testing kits. We all hope a reliable vaccine will be found soon, allowing a return to something like normal, whatever that may be.

HepcoMotion has been working closely with world leading pharmaceutical manufacturers to produce machines that manufacture COVID-19 test kits on a global scale. Right from the outset of this pandemic, Hepco’s Korean branch has been on the frontline. Korea’s national approach to tackling COVID-19 has been based on a strategy of large scale testing, and in response, major pharmaceutical manufacturers immediately looked for reliable, proven solutions to meet this demand.

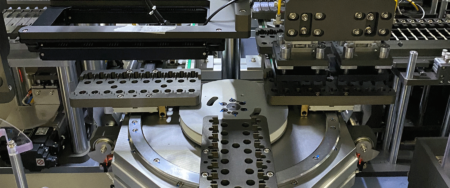

When selecting a reliable track system to guide these test kits through the assembly and testing process, one of Koreas leading pharmaceutical manufacturers reached out to Hepco. In this application each machine relies on a 1.5m DTS – Driven Track System. 10 kits are mounted on each carriage. Vision equipment is used for a final inspection which is completed within 1 second. 5000 kits are produced per machine per day.

Compared to other mechanical transfer technologies, the large space at the centre of a DTS track system allows for additional manufacturing equipment to be positioned inside the track system. This feature reduces the overall machine footprint, which in turn increases capacity for the number of machines in a given space, ultimately increasing the output of these highly demanded kits.

To meet demand each system is in operation 24 hours a day, 7 days per week. With a requirement for minimum maintenance, such a schedule could provide a challenge for most systems. The DTS system relies on Hepco’s V guide technology, which is an inherently low maintenance product. Hardened V edges on both track and the bearing ensure a longer system life, and when wear does occur an eccentric adjustment feature means that bearings can be quickly adjusted against the track, preventing costly time required to replace the entire system.

Built in bleed lubrication also saves time and cost, ensuring a constant source of lubrication to the running surfaces, removing the need to halt production for regular lubrication intervals.

Thanks to Hepco’s 50 years of experience and expertise in the field of linear motion and transfer technology, the UK based company was able to meet the demanding production schedules of this application. Outside of Korea, Hepco’s high-speed transfer products have also been a ‘go to’ solution for test kit production and general testing applications. At a time when many large pharmaceutical companies are under pressure to produce reliable, low maintenance machines quickly, Hepco’s trusted technology and reputation for outstanding performance is proving critical in the fight against this pandemic.