Article classificationArticle

HepcoMotion FLEXIBLE PACKAGING MACHINERY DTS2

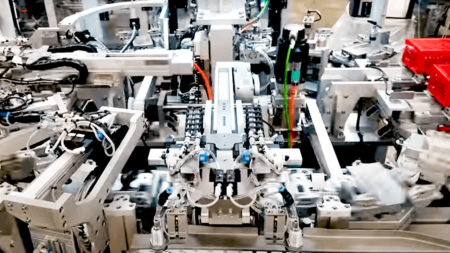

Colin Mear Engineering is at the forefront of innovation when it comes to the packaging industry. Amongst their most recent projects, a solution was required to produce a new, flexible, multi-purpose packaging machine that would enable a high product throughput, all within a compact space.

The machine would need to take the product and pack it into a 2-piece container; this container would then be inserted into a foil envelope, sealed and offloaded at a rate of 84 pieces per minute. At the core of this machine, Colin Mear Engineering required a precise and reliable carousel system to perform the functions over long periods with minimal maintenance.

Solution

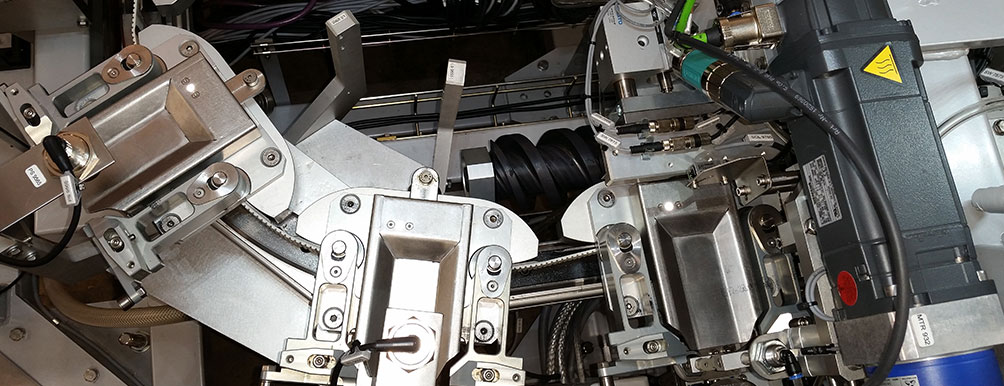

HepcoMotion’s unrivalled DTS2 driven track system offered the ideal solution. The design used a twin drive scroll system that provided a direct and highly dynamic drive, enabling an index distance of 500mm to be achieved in just 0.5 seconds – a key factor in achieving the 84 parts per minute target. The linked track system offered an accurate and repeatable indexing movement, a vital requirement when items are being processed in such a short cycle time.

Scope of supply

A DTS2M was supplied with 16 carriages equally spaced around the rectangular format track system. Due to the high acceleration forces required to meet the indexing time, two linked drive scrolls, driven by a single servomotor, provide the drive. This specification allowed the transfer of payload of up to 2Kg per carriage to be indexed over 500mm in just half a second.

Result

The unique design of the DTS2 driven track systems has enabled Colin Mear Engineering to develop a ground breaking packaging line that can be used in multiple industries, such as food, tobacco and pharmaceutical. The system has been designed with the flexibility to run different products with minimal change over time, leading to considerable cost benefits for the user. The performance and small space taken up by the system along with virtually no maintenance has provided an optimal solution that runs seamlessly within the packaging line.