Article classificationArticle

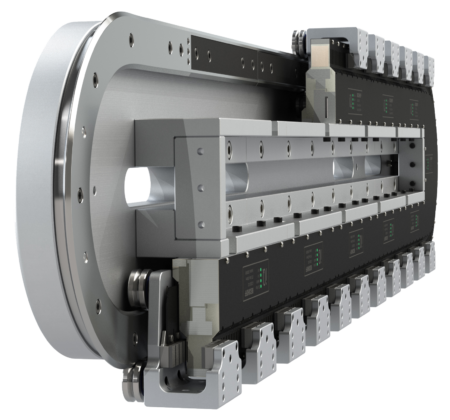

HEPCO V GUIDE SYSTEMS: THE BREAD AND BUTTER FOR FOOD APPLICATIONS XTS GFX boot system

One of the largest industries globally, the food and beverage industry is a core element of the UK manufacturing economy. Comprising of many different sectors including the bakery sector, confectionary, meat processing, drinks industries, dairies and fish processing – the range is wide and demand is high.

The fundamental element of any food manufacturing application is how to guide and transfer the components around the system. Whether it’s carton forming, pre-feeding, pick & place, or filling, the components need to move between processes, and it is the guidance system that provides the necessary linear or circular movement for this. The standard choice for many designers based on purchase price alone is likely to be ball rails, and in many situations, this type of system will meet the demand of the application. However, the packaging industry is notoriously demanding and highly competitive with high speeds, short travel strokes and high throughput. In this type of environment, with the hourly downtime costs to consider and the required system life, alternatives such as Hepco’s V guide systems can offer a cost saving over the total cost of ownership of the system.

V guide system

Hepco’s V guide system was conceived to meet the challenges faced by packaging manufacturers; low maintenance, ease of installation together with solutions that can perform in any environment. Marking its 50th anniversary this year, Hepco has extensive experience providing a range of high speed and accurate solutions for the food industry. Hepco’s V guide technology functions on the basis of tight geometrical control over matching slide and bearing V’s.

In turn this provides a wiping action in operation with the speed of the bearing at its circumference being faster than the speed at the root diameter of the V. The resulting action causes dirt to be pushed to the extremities of the bearing, allowing dirt and debris to be wiped away. Components that can reduce the ingress of dirt will be quicker and easier to clean, allowing quicker cleaning cycles and therefore less downtime. With many food applications working 24/7 and processes becoming ever more automated, the need for equipment and machinery to be reliable and efficient is vital to production. One key way to maximise production and increase profit is to minimize downtime.

Minimizing downtime

Downtime is one of the biggest challenges in food manufacturing due to the cost implications associated with it. Every minute a machine is not up and running equates to lost time that could be spent creating a product that contributes to profit. Food packaging applications need to stay on schedule and produce high product throughput with utmost reliability in order to be profitable.

Downtime is costly whether it is planned or unplanned. Downtime per hour, per system differs dramatically between industries and specific manufacturers. Customers within the food packaging industry have downtime costs varying from £500 – £100,000 per hour, highlighting how longer downtimes can really impact on businesses. Minimizing downtime is a key driver for many customers and Hepco’s V guide system offers a real advantage by reducing maintenance time with features such as minimal re-lubrication intervals, the ability to eccentrically adjust bearings and offering a longer system life.

Lubrication

Due to the high speed, high throughput requirements in the food industry, lubrication is essential to minimize friction and wear, dissipate heat, prevent corrosion and ultimately to extend the system life. Ball rails rely on consistent, effective lubrication in order to reduce wear of the recirculating balls and associated rails. Re-lubrication intervals are far shorter for ball rails than Hepco’s V guide systems, with frequent maintenance and downtime required to keep them running.

Re-lubrication intervals for ball rails will vary depending on the condition but manufacturers state clear distances for re-greasing often as low as 50km. Re-lubrication intervals are far longer for V guide systems and less lubricant is required to work effectively, saving valuable downtime and cost. It is not unusual for intervals of up to 1000km of travel before having to apply additional lubrication to the bearing cap seal.

Systems that can deliver continuous operation, without the need to be regularly stopped for routine maintenance such as re-lubrication, are highly valued by designers and production engineers alike.

V guide systems can also use an automatic lubrication system which delivers lubricant directly to the contact surface between the slide and the V bearings. Customers such as Bosch Packaging Technology use this in their award-winning Kliklok Integrated Topload Cartoner (ITC) system. Offering the highest speeds available for a solution with such a small footprint, the system operates at 2.5m/s and up to 80 cartons per minute are formed, loaded and closed on the ITC. High product throughput is a key requirement, therefore low maintenance is a must.

The system uses a 6m long GFX Guidance System for Beckhoff XTS eXtended Transport System with 10 x three-bearing, size 34 1-Trak movers. Food grade grease is released though Hepco’s integrated bleed lubrication facility ensuring that lubrication is constantly supplied. This means that the system does not need to be stopped at regular intervals for re-lubrication, reducing downtime and increasing machine efficiency. When the remotely located lubrication canister comes to the end of its life, it is simply replaced while the track system is still moving.

A further point to note is that ball rails will eventually purge any lubrication from within the block, leading to catastrophic failure if not re-lubricated regularly. The cost implications of a catastrophic failure is severe in terms of significant downtime, lost production, and cost of replacement parts and labour. Conversely, should the V guide maintenance be neglected, the system is capable of running dry, albeit at a limited duty, but will not critically fail in the same way that recirculating technology would.

System Life

Packaging applications are highly demanding, and an expected machine life of over 10 years is typical. In a relatively clean environment, it can be expected that linear systems within a typical packaging line will need replacing at least once during this period. When replacing a ball rail system, both the block and rail must be discarded even if the rail shows no sign of wear. This is because the block and rail are closely matched together, and cannot tolerate standard replacement component parts once the system has been worn in. Throwing away the entire system when only part of it is worn is not only expensive, but very wasteful and environmentally unfriendly.

When a Hepco V guide system shows signs of wear, the eccentric adjustment facility of the V bearings can be used to quickly and simply remove any play that has occurred. When the V bearings reach the end of their calculated life, they can be replaced individually, and not as an entire set, so perfectly good components do not have to be discarded unnecessarily.

Replacing components

If a component needs replacing, time is of the essence to minimize the downtime and the loss of production. An average Hepco GV3 carriage for example, can be changed in less than 10 minutes, compared to each ball rail system taking approximately 30 minutes. This time saving has an impact on not only the hourly maintenance costs, but also on the downtime costs, making the Hepco system far more attractive from a maintenance perspective.

Washdown

In food production, cleanliness is paramount and frequent washdowns are a necessity. Some washdown processes use only water, but most use chemicals and detergents which present an additional challenge to the machinery components. Due to the frequent, high-pressure washing and sterilisation, stainless steel is the preferred material as it is able to withstand harsh and caustic washdown environments without corroding or oxidizing.

One of the key benefits of Hepco’s V guide systems for those involved in food and beverage processing is that stainless steel is a standard choice. Hepco’s SL2 stainless steel linear guide is not priced as a ‘special’ and not subject to long lead times. Furthermore, HepcoMotion provides a range of stainless steel and corrosion-resistant elements that can be mixed and matched so that the optimum combination of hygiene, wear and performance can be achieved.

Noise

A final point to raise is that a V guide system running at high speed is comparatively quieter than a ball rail due to the minimal point contact and circular motion of the balls in the bearing. The re-circulating nature of the ball arrangement in a ball rail causes notable mechanical noise at high speeds. Packaging applications generally operate at high speeds where health & safety, and noise pollution are very serious considerations, so the noise level of the machine components are often an important factor.

V guide technology has many design and application benefits over traditional ball rail products that are particularly suited to the high speed, high volume and low maintenance food industry applications. With over 42 major product lines with thousands of individual components – including the SL2 stainless steel linear guide, PRT2 ring guide and track for circular motion, DTS driven track system and a wide range of belt driven and ball screw actuators, Hepco’s range of products can meet practically any food industry requirement. Hepco’s newest addition, the GFX Guidance System for Beckhoff XTS Transport System is rapidly being adopted in the packaging industry for applications where users are looking to benefit from vastly improved production rates with the ability to make on the fly product changes.

V guides have proven to be highly effective in hostile food industry environments and when the longer term maintenance costs and reliability are considered, V guides offer a solution not often seen in other systems.