Article classificationArticle

GV3 HARSH ENVIRONMENT V-shaped guide rail

Production lines producing brake pads are particularly damaging to linear guidance systems as the amount of dust in the atmosphere forms an aggressive film over all components. Hostile conditions like this call for a solution that will cope, not only with the dust, but also provide a good service life to keep control over maintenance costs.

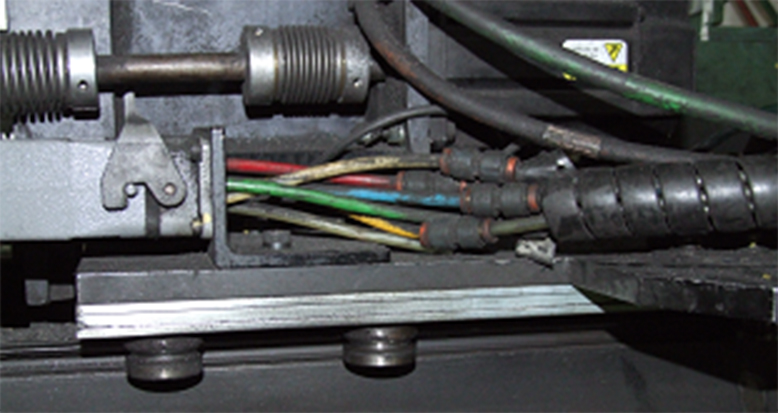

This brake pad manufacturer is well aware of the challenges and turned to Hepco to supply the linear guidance products in such environments. The application depicted above is relatively simple enough in respect of movement. A head mixes the correct amount of brake pad material and places this in a mould. The mould is then heated and compacted to produce the final product. The linear system provides the motion to move the mould in and out of the compacter over a distance of 300mm

Solution

A GV3 double edge slide size 44 x 450mm long with an extended carriage to enable access to the compacter. No lubrication is used relying on the self cleaning action of the vee bearings wiping on the slide. A lubricated system with cap seals would under these conditions form an abrasive paste which would wear the slide quickly. Double row bearings ( DR) are specified to preserve bearing life.

Scope of supply

NM44 P3 x 450mm 2 x SJ34CDR, 2 x SJ34EDR bearings

Result

This is a fine example where it is favourable to leave the wiping action of the GV3 principle to solve the problem. Cap wipers covering bearings and lubricating the slide vees are preferred in many hostile conditions. This is on the basis that it’s better to prevent the dirt getting to the bearing v’s in the first place. However, brake pad dust and oil are not the best combination for preserving slide wear. A dry running system would allow the slide to perform better, albeit with reduced load capacity but an acceptable life. GV3 systems in these environments are known to last a number of years before replacement is needed, any slide wear can be taken up by readjusting the eccentric bearings to take out the play that eventually occurs.