Article classificationArticle

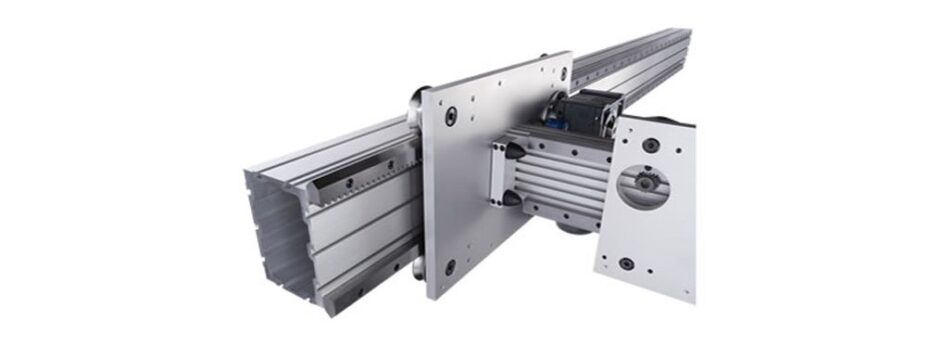

IAC USE AUTOMATION TO REDUCE HEALTH AND SAFETY RISK AND SAVE TIME HDS2 Heavy linear guide

Industrial Automation & Controls Ltd (IAC) is a large electrical integration and automation company based in South Wales; they provide solutions to the manufacturing industry. Their customer has a requirement to install a handling solution for the manipulation of polymer billets.

The billets are 10Kg each and when they come out of the curing oven, the billets are at a temperature of 150°C. Previously the polymer billets have had to be manually handled by an operator. The high temperatures pose a health and safety issue, which has driven the decision to automate.

Additionally, the customer is committed to installing SEW geared motors, so it is imperative that the solution is able to accommodate. This is not always an easy task and required IAC to source a product with a custom interface.

The cycle time for the process is 45 seconds, and the customer was keen to find a solution that would reduce the time.

Solution

HepcoMotion specified a fully rack driven HDS2 X-Y-Z gantry solution that provided an X-axis stroke of 1100mm, a Y-axis stroke of 2800mm and a Z-axis stroke of 1500mm. Based on an overall payload of 150Kg, MOD 2.5 racks were utilised for the horizontal X and Y-axes and a high capacity MOD 3.0 rack for the vertical Z-axis. The system was supplied complete with cable chains and custom drive flanges to mount the SEW geared motors.

Scope of Supply

X-Y-Z pick and place gantry system.

X-axis

2 x HB25 aluminium beams at 2100mm long fitted with single edge HD slides, one slide with MOD 2.5 rack option on each beam, one beam fitted with vee slides, the opposite with flat track to ease setting up. Carriage fitted on each rail with 64mm bearings/58mm track rollers, capwipers, auto-lube devices and special drive flange to suit SEW WAF37 geared motor. Connection shaft kit to connect both x axis drives.

Y-axis

HB25 aluminium beam at 4000mm long fitted with single edge HD slides, one slide with MOD 2.5 rack option.

Fitted Y-Z common carriage assemble 700mm x 700mm complete with 95mm bearings on Y axis and 64mm bearings on Z axis, cap wipers, pinion auto-lube devices and special drive flanges for SEW WAF37 on Y axis and SEW WAF47 on Z axis.

Z-axis

Compact HD beam HB25C at 2800mm long, fitted with HD single edge slides, one slide with MOD3.0 rack option. End of beam tapped with 4 x M12 holes for mounting of customer tooling.

Result

HepcoMotion was able to supply a complete mechanical system tailored to suit the customer’s needs. The ability to accommodate the SEW geared motors, provide 3D models and give full technical support throughout the sale, manufacture and installation process has ensured a successful partnership on this project. Hepco and IAC have been able to work closely with SEW to ensure that both mechanical and electrical elements are perfectly matched. The result is a reliable system that not only provides manufacturing efficiency, but also takes operators out of a potentially harmful situation. Moreover, the system provides a considerable time-saving for the customer.