Article classificationArticle

HEPCOMOTION LONDON 2012 OLYMPIC CAULDRON APPLICATION

Being involved in the Olympic games is surely the highlight of any athletes career but when British designer Thomas Heatherwick was chosen to the cauldron for the 2012 London games he must have thought that he had struck gold.

Whilst clearly honoured to be trusted with the project, the task proved challenging with many hurdles to overcome. Having fought the first one to have the cauldron in the main stadium, the brief to build something that connected all nations with a story, became complicated with the request that no moving parts be used.

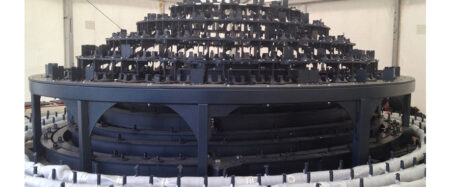

The final impressive solution, 16 tonnes in weight; 8 metres across when flat and 8.5 metres high, actually had the most moving parts of any cauldron in history. Only quality parts with a proven track record were chosen, this was not a project for experiments.

Solution

The Olympic cauldron comprised 204 petals whereas the Paralympic had 164, each one representing a competing nation. There were three tiers of the cauldron which housed holders for the stems where the petals were placed by a child accompanying each of the teams. When all alight the stems rose slowly from the floor and converged to form an upright cauldron with a single, massive flame.

What was not clear from the pictures at the time, was the clever mechanism that allowed each of the three tiers to be raised at a consistent rate. At the heart of this mechanism were 16 Hepco Zimm ball screw jacks providing the lift for the arm linkage.

Scope of Supply

4 sets 25×5 MSZ10 x 350mm stroke, 12 sets 32×10 MSZ25 x 350mm stroke and 4 sets 40×10 MSZ50 x 350mm stroke. All sets were ball screw jacks.

Results

Arguably the best ever cauldron seen at an Olympic games which, as we now know, opened and closed successfully. The closing process was simply a reverse of the opening ceremony, with the stems being drawn in by the jacks until the cauldron was flat on the ground, and the flames in the petals extinguished one by one.

A successful operation of the Hepco Zimm screw jacks even if they did only see two cylces; the quality and number of options within the range were key factors in their choice along with the need for a reliable delivery time.