首頁 > Shopping Cart > Linear Guideway Characteristics

-

Information

-

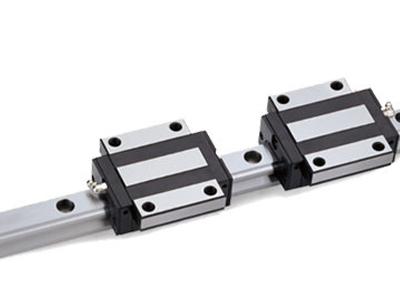

Linear Guideway-MSA-S/E Heavy load series Compact Linear Guideway

Linear Guideway-MSA-S/E Heavy load series Compact Linear Guideway -

Linear Guideway-MSB-S/E Low assembly series Compact Linear Guideway

Linear Guideway-MSB-S/E Low assembly series Compact Linear Guideway -

Linear Guideway-MSC/D Miniature Miniature Linear Guideway

-

Linear Guideway-MSR Full Roller Full Roller Linear Guideway

-

Linear Guideway-SME Ball Chain Ball Chain Linear Guideway

-

Linear Guideway-SMR Roller Chain Roller Chain Linear Guideway

Characteristic

High positioning accuracy, high repeatability

Linear guideway is a design of rolling motion with a low friction coeffi cient, and the diff erence between dynamic and static friction is very small. Therefore, the stick-slip will not occur when submicron feeding is making.

Low frictional resistance, high precision maintained for long preiod

The frictional resistance of a linear guideway is only 1/20th to 1/40th of that in a slide guide. With a linear guideway, a well lubrication can be easily achieved by supplying grease through the grease nipple on carriage or utilizing a centralized oil pumping system, thus the frictional resistance is decreased and the accuracy could be maintained for long period.

High rigidity with four-way load design

The optimum design of geometric mechanics makes the linear guideway to bear the load in all four directions, radial, reversed radial, and two lateral directions. Furthermore, the rigidity of linear guideway could be easily achieved by preloading carriage and by adding the number of carriages.

Suitable for high speed operation

Due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation.

Easy installation with interchangeability

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of linear guideway gives a convenience for installation and future maintenance.

Accuracy standard grade

The accuracy of linear guideway includes the dimensional tolerance of height, width, and the running accuracy of the carriage on the rail. The standard of the dimension di erence is built for two or more carriages on a rail or a number of rails are used on the same plane.

The accuracy of linear guideway is divided into 5 classes, normal grade (N), high precision (H), precision (P), super precision (SP), and ultra precision (UP).

Running parallelism

The running accuracy is the deviation of parallelism between the reference surface of carriage and reference surface of rail when carriage moving over the entire length of rail.

Height difference(ΔH)

The height difference (ΔH) means the height difference among carriages installed on the same plane.

Width differenc(ΔW²)

The width difference (ΔW2) means the width difference among carriages installed on a rail.

Note:

When two or more linear guideways are used on the same plane, the tolerance of W2 and di erence of ΔW2 is applicable to master rail only. Note: The accuracy is measured at the center or central area of carriage. Note: The rail is smoothly curved so that the required accuracy is easily achieved by pressing the rail to the reference surface of the machine. If it is mounted on a less rigid base such as an aluminum base, the curve of the rail will a ect the accuracy of the machine. Therefore, it is necessary to de ne straightness of the rail in advance.The Selection of Accuracy Grade The accuracy grade for different applications shown as table below.

Preload and rigidity

The rigidity of a linear guideway could be enhanced by increasing the preload. As shown as above figure, the load could be raised up to 2.8 times the preload applied.

The preload is represented by negative clearance resulting from the increase of rolling element diameter. Therefore, the preload should be considered in calculation service life.

The Selection of Preload

Selecting proper preload from table below to adapt the speci c application and condition

Applicable preload level for each model

The preload levels of each series are shown in the table below, where the preload size is a percentage of the basic rated dynamic load (C). For the basic rated dynamic load (C), please refer to the specification table of each series.

Mounting

1、Installation of Linear Guideway When Machine Subjected to Vibration and Impact

◎Installation of rail

Step 1

Prior to installation, the burrs, dirt, and rust preventive oil should be removed thoroughly.

Step 2

Gently place the linear guideway on the bed, and pushing it against the reference side of bed.

Step3

Check for correct bolt play and temporarily tighten all bolts.

Step4

Tighten the push screw in sequence to ensure the rail close matching the reference side of bed.

Step5

Tighten all bolts to the speci ed torque. The tightening sequence should start from the right side to the left side. By doing this, the original accuracy could be achieved.Step6

Follow the same procedure for the installation of remaining rails.◎Installation of carriage

Step1

Gently place table onto carriages and temporarily tighten the bolts.

Step2

Tighten the push screw to hold the master rail carriage against the table reference side, and position the table.

Step3

Fully tighten all bolts on both master and subsidiary sides. The tightening process should be followed by the order of to .2、Installation of Linear Guideway without Push Screws

Installation of master rail

Using a vise First tighten the mounting bolts temporarily, than use a C vise to press the master rail to reference side. Tighten the mounting bolts in sequence to speci ed torque. ◎Installation of subsidiary rail

Using a straight edge

Place a straight edge between the two rails and position it parallel to the reference side rail which is temporarily tightened by bolts. Check the parallelism with dial gauge, and align the rail if necessary. Then tighten the bolts in sequence.

Using a table

Tighten two master side carriages and one subsidiary side carriage onto the table. Then temporarily tighten another subsidiary carriage and rail to the table and bed. Position a dial gauge on the table and have the probe of dial gauge contact the side of the subsidiary carriage. Move the table from the rail end and check the parallelism between the carriage and the subsidiary rail. Then tighten the bolts in sequence.

Compare to master rail side

Tighten two master side carriages and one subsidiary side carriage onto the table. Then temporarily tighten another subsidiary carriage and rail to the table and bed. Move the table from one rail, check and align the parallelism of subsidiary rail based on moving resistance. Tighten the bolts in sequence.

Using a jig

Using the special jig to align the parallelism between the reference side of master rail and that of subsidiary rail from one rail end to another. Tighten the mounting bolts in sequence.3、The Installation of Carriage of Linear Guideway without the Reference Side for Master Rail

The running accuracy can be obtained by tightening the two carriages onto the measuring plate. A dial gauge or autocollimeter is sued for measuring the accuracy. If a dial gauge is used, the straight edge should be placed as close to carriage as possible for accurate measurement.

4、Accuracy Measurement after Installation

The running accuracy can be obtained by tightening the two carriages onto the measuring plate. A dial gauge or autocollimeter is sued for measuring the accuracy. If a dial gauge is used, the straight edge should be placed as close to carriage as possible for accurate measurement.

5、The Recommended Tightening Torque for Rails

The improper tightening torque could a ect the mounting accuracy, so tightening the bolts by torque wrench to speci ed toque is highly recommended. Di erent types of mounting surface should have di erent torque value for applications.

Using a temporary reference side

Two carriages are tightened together onto the measuring plate, and set up a temporary reference surface near the rail mounting surface on the bed. Check and align the parallelism of rails and then tighten bolts sequentially.

Using a straight edge

At first temporarily tighten rail onto the bed, then use a dial gauge to align the straightness of rail. Tighten the bolts in sequence. -

-

Q&A