Article classificationArticle

CUTTING-EDGE ELECTRIC VEHICLE BATTERY PRODUCTION USING HEPCO’S V GUIDE SYSTEMS GV3 Linear Guides

Global concern for the environment continues to drive developments in green technology and this is particularly notable in the increase in demand for electrical vehicles. As uptake of electric vehicles (EVs) increases, the EV battery industry has needed to grow in tandem. The specific benefits of HepcoMotion’s V guide system have proved invaluable in satisfying the requirement for new production facilities and processes.

Linear motion expert HepcoMotion is currently excelling with applications in the expanding EV sector. With a dedicated sales office in South Korea, UK-based HepcoMotion specialises in high quality linear and circular solutions and automation components. Celebrating its fifty-year anniversary this year, HepcoMotion has gained a reputation for its high-end, low maintenance products. The top three companies in Korea’s battery market are investing heavily in the production of EV batteries worldwide and HepcoMotion is supplying to all of them; SK Innovation, LG Chemical and Samsung SDI.

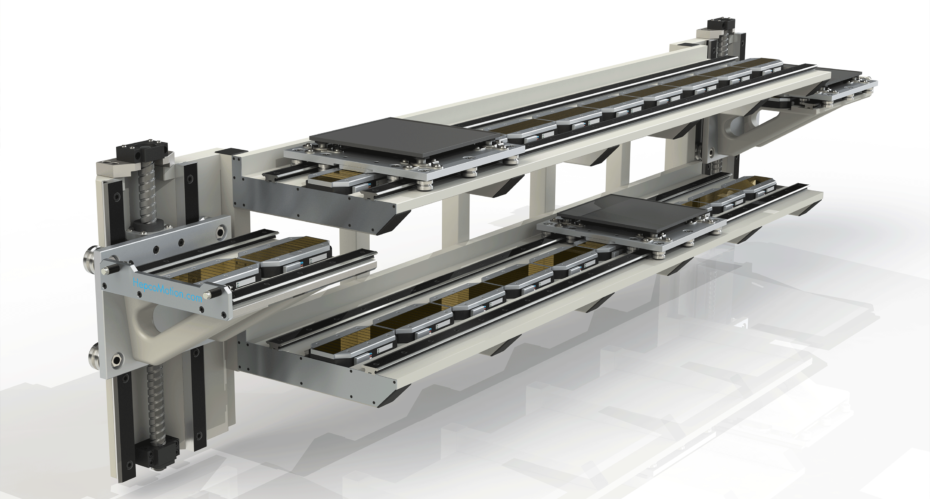

Vertical closed loop track system

The composition of an EV battery varies depending on the type of electric vehicle, but generally, EV batteries are composed of individual battery cells and modules which come together to form a pack. The battery for a BMW i3 for example comprises of 96 battery cells. Twelve cells are combined into one module and eight modules come together to form one pack. The manufacture of EV batteries therefore requires many elements to be combined together making it particularly suited to long line manufacturing. Space is often at a premium however, making a compact, space-saving system high on the agenda. Production formats vary but the key EV battery manufacturers all use a vertical closed loop track layout, which offers significant benefits by optimizing the space in a 3D capacity. The footprint remains the same but production can be doubled by having two productions lines running in parallel, vertically aligned, one above the other. A small length of track, vertically moved by an actuator connects the lower and upper tracks. Not only is this system space saving but it also maintains the product in a single orientation; advantageous in EV battery production.

With a vertical closed-loop track layout there is a small gap between the main production line and the short length of track that moves vertically to connect the upper and lower tracks. A traditional conveyor system or a ball rail system for example, are not able to cope with this gap. Indeed, it can be challenging for many linear guidance systems to cope with gaps and provide the seamless guidance required for the carriage to traverse. Hepco’s V guide systems are able to traverse joints or gaps making them a popular choice in EVB applications.

Cutting-edge production by key Korean conglomerates

SK Innovation, South Korea’s leading oil and chemical company, has been mass producing EV batteries since 2012 and is set to increase its EV battery production capacity with expansions into Europe and the US. Producing pouch type EV batteries for customers such as Volkswagen, SK Innovation is one of the top battery suppliers for electric vehicles. In South Korea, SK Innovation utilise an impressive 104 metres of Hepco’s core GV3 track, arranged in a vertical closed-loop track layout, 50 metres long and 2 metres high. Well suited to long lengths, GV3 can be specified to any length, supplied as butted sets to fulfil longer length requirements such as this. GV3 is a superior V based linear motion range designed to serve a diverse range of automation and linear applications.

Typically operating at 1m/s with a 20kg payload, the movers move around the system via dynamic track sections that vertically align with adjacent tracks, providing a sizeable flow process through various stages of production. SK Innovation use Hepco’s 6 bearing carriages, which are able to traverse gaps as four bearings are always in contact with the rail when traversing the gap, keeping the carriage parallel. A centrally mounted linear motor unit independently moves the carriages, providing complex sequences of movement for individual carriages.

Leading Korean Chemical company, LG Chem also use Hepco’s GV3 linear guide in their automated system producing EV battery film. Again a vertical closed-loop system is employed and the GV3 linear guides are supplied as butted sets to fulfil the 20m circuit. With a wide portfolio of products and a variety of different configurations ideally suited to EV battery manufacture including singe-edged slides, 6 bearing carriages, and assembled carriages with added top-plate, HepcoMotion has a solution to meet practically any requirement.

Low maintenance

One of the biggest challenges in the EV industry is producing the output to match the demand. This is an exponentially growing market and as with all applications requiring high throughput, low maintenance is core to optimizing production processes. A low maintenance solution means less manpower, less downtime which equates to a significant cost saving. Conveniently, when a Hepco V system shows sign of wear, the process is simple and does not impinge too much on production time. The eccentric adjustment facility of the V bearings can be used to quickly and simply remove any play that has occurred. Moreover, when the V bearings reach the end of their calculated life, they can be replaced individually, and not as an entire set, saving both time and money. A key point to note is that a V guide system will not fail catastrophically meaning excessive downtime and a complete system change will be avoided.

Corrosion resistant

The chemicals involved in the manufacture of EV batteries means that corrosion resistant materials are often required. One of the key benefits of Hepco’s V guide systems is that stainless steel is a standard choice. Hepco’s SL2 stainless steel linear guide is not priced as a ‘special’ and not subject to long lead times. Furthermore, HepcoMotion provides a range of stainless steel and corrosion-resistant elements that can be mixed and matched so that the optimum combination of hygiene, wear and performance can be achieved.

HepcoMotion’s SL2 is a core component in systems for South Korean electronic component maker, Samsung SDI, the world’s largest supplier of lithium-ion batteries. 2 x SL2s are arranged in parallel, supplied as joined sets to fulfil the 20m circuit, where a number of key processes are performed.

This application requires a consistent level of precision to ensure SL2 carriages, which carry the product are aligned correctly to production equipment and processes. Operating at 2m/s with an 80N payload, this is a high duty application.

Compliance

A further reason why Hepco is often favoured in this type of application is due to its high compliance.

Mounting to an uneven surface can be time-consuming and costly. The unique design of Hepco’s V bearing allows it to perform when mounted to un-machined or uneven surfaces. GV3 twin bearing are constructed from two pieces, and therefore allow a small amount of compensation for deviation in mounting surface flatness. Ball rail systems cannot tolerate any deviation in mounting flatness, and require surfaces to be machined prior to installation. For customers such as SK Innovation that use 2 x 50 metre guides, the ability to operate effectively without machining these surfaces is a big time saver.

As electric vehicles continue to move towards becoming a viable choice for mainstream drivers, the long-term outlook on the electric vehicle battery market looks positive. With end users including SK Innovation, LG Chem and Samsung SDI, Hepco’s V guide systems meet the demanding needs of the biggest EV battery producers, and are a key production element contributing to a cleaner, environmentally friendly future.