Article classificationArticle

SELECTING THE RIGHT GUIDE SYSTEM FOR YOUR APPLICATION GFX XTS

During the design of a new machine, choosing the correct guide system is one of the fundamental decisions to make. Factors such as speed, positional accuracy, payload and environmental conditions play a key part in the decision for or against a certain design of guide system. In this overview, we show how different guide products from HepcoMotion are able to meet each of these factors.

Drive Type: Positional accuracy versus speed

Before approaching “which linear guide?”, it is important to consider requirements of the application in terms of the drive type. The most common drive types are screw, rack & pinion, belt drives and linear motors. Each of these types of drive has its pros and cons, giving them strengths in different areas of use.

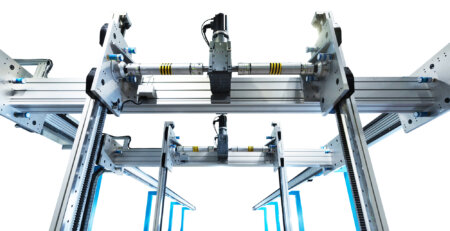

In many applications, positional accuracy and speed are key parameters that determine the most suitable type of drive. This is not the only reason for the increasing popularity of linear motors. Linear motors enable high speeds in combination with precise movement. Above all, however, linear motors enable individual control of carriages. This gives greater flexibility in a production cell, where on-the-fly changes are sometimes required on a daily basis. Nevertheless, there are other factors to consider; the original Beckhoff XTS system (one of the market leaders in linear motor drives) is designed for transport of light payloads. HepcoMotion’s specially developed guidance system, GFX, used in combination with the XTS linear motors, overcomes this limitation. An XTS system used in combination with GFX is capable of a 50N capacity at speeds up to 4m/s, with a repeatable accuracy of less than ±10 μm. However, it should be considered that this type of system requires higher initial investment due to its complex electronics. This initial investment may be worthwhile in many cases, but not all.

When one looks at traditional drive systems, it is still important to be clear about the goals to be achieved. For example, a ball screw will provide a high level of accuracy – typically ±0.05mm. A toothed belt drive will achieve approximately ±0.1mm and for a rack and pinion drive an accuracy of ±0.3mm is assumed. In terms of speed, a ball screw cannot achieve the same speeds as a belt drive and its length is limited based on speed.

Rack and pinion drives are also limited by speed, but do not have the same limitation on length. When specifying a drive system, you have to balance several features – you cannot look at each element in isolation. A short stroke can be achieved more quickly with a screw drive because of the high rate of acceleration required. Racks and pinions are more commonly employed on longer axes where the rate of acceleration can be lower to achieve the same maximum speed.

The installation orientation of the components is also a consideration. In vertical applications, some drives may offer an advantage due to their high capacity. Belt drives may also be suitable, providing the tensile capacity of the belt is sufficient to support the payload. Additional support may be required, but can encroach on the available space envelope beneath the payload. An exception to this is the DTS+ and DTS2 product ranges, which are designed such that they can operate in any orientation.

Rack drives are commonly used in multi-axis systems. Z-axis assemblies can be arranged such that the beam and slides are the moving component and the motor and carriage plate remain fixed, reducing the mass of moving components. Where a customer requires a complete gantry or multi-axis solution, HepcoMotion can deliver its products as a complete system, with drive and axis connections fully specified. In the case of ring and track solutions, the DTS product range is unrivalled in its market.

Which guide system?

Once the question of drive type has been addressed, focus shifts to the type of guidance required. The decision will depend primarily on design, environment of use and payload. Will straight, curved or multi-axis motion be required? HepcoMotion can offer guidance products for any of these motion types, across a wide range of payload requirements. In principle, every motion type can be offered with our without drive. For example, the GV3 product can be offered with single, or double-edged slides and racks so that a pinion-driven carriage can be mounted to them.

For linear motion, HepcoMotion’s high quality GV3 product impresses with its large range of configurable components, allowing maximum compatibility and the ability to tailor to customer requirements. Additionally, slides can be butt joined to lengths longer than the standard supply. For applications where standard, prefabricated slide lengths & carriages can be accommodated, Simple Select is a good choice. Delivery of this ready-made product is rapid and carriages are shipped assembled to slides to facilitate a quick installation. For an application that includes curved motion, either as a combination of straights or rotary motion, PRT2 will be the right choice.

In addition to accuracy and type of drive, environmental conditions are the second key aspect in product selection. Applications in food and pharmaceutical industries often demand stainless steel components. HepcoMotion’s SL2 product range is the stainless steel equivalent to the extensive GV3 linear guide system. Many other Hepco ranges are also available with stainless steel options. In some situations, corrosion resistance is of importance. Specialised components are required for extremes of temperature and vacuum environments; Hepco can provide products to meet these needs. Our vacuum and extreme temperatures are often used in the manufacture of semiconductors, production of LCD and OLED screens and in vacuum chambers and are suitable for temperatures ranging from -50°C to +210°C.

In many cases, dust and dirt are common features of production environments. This can cause issues in traditional recirculating ball products where the raceways are exposed to dirt and dust and can experience premature wear and failure.

This is not the case for Hepco’s V-guide systems. The design of the V-bearings is such that the internal structure of the bearing is shielded from dirt and dust particles. The V-guide system has a unique wiping action that tends to expel debris at the interface between bearing and slide. In this way, the slide system is unaffected by ambient conditions and life is not limited. Most of Hepco’s guide systems are based on this V technology and are ideally suited to use in harsh environments with high levels or dirt and debris.

Payload

The final element to consider when specifying a product is payload. For weights of up to approximately 400kg our GV3 linear system (or PRT2 for curved/rotary motion) is recommended. For larger payloads, up to approximately 68kN, our heavy duty guide systems (HDS2 for linear and HDRT for curved/rotary) are a better solution. Both systems are based on V-guide technology and available with stainless steel components. The MHD system is designed specifically for moving large payloads and uses bearing blocks fitted with roller bearings to do this. MHD roller bearings are sealed and lubricated for life internally to preserve the life of the internal recirculating balls and taper rollers. MHD tracks comprise hardened and ground flat track, which is available with or without an integrated rack profile, allowing a pinion to be mounted to a carriage plate to drive the system. The MHD roller bearings are able to compensate for misalignment saving design and assembly time.

Whatever the requirement, HepcoMotion’s systems offer versatility across a large range of applications. Systems can be purchased in component form – this modular approach gives the designer a high level of flexibility when specifying a system. Additionally, the V-guide technology is capable of extremely long service life; should play develop in a system, bearings can be adjusted to reset the carriage, removing the need to replace the whole slide system and carriages (common with traditional recirculating ball products). By checking the details of your application and carefully specifying products, our Technical Sales team will ensure the life and service requirements of your system can be met.

The drive and guidance systems form the heart of any production cell. Choosing the correct system is extremely important. To ensure the correct specification of products for an application, various parameters must be considered and balanced. This requires a clear idea of the goals of a project, trust in the quality of components and their ability to perform.